| Proton Linac Development Division |

|

|

Development of Beam Dump for 10 mA, 3 MeV Proton Beam

A beam dump will be required to absorb 3 MeV proton beam coming out from Radio Frequency Quadrupole (RFQ). The beam would be pulsed in nature with a peak current of 10mA with a repetition rate of 50 Hz and duty factor of 10% resulting in a beam power of 3 kW.

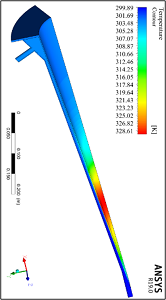

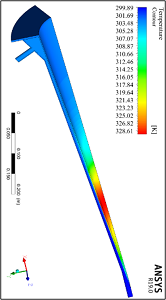

Beam dump design involves material selection, thermal hydraulic analysis followed by its structural analysis. Design of a Beam Dump for 3 MeV, 1 mA proton beam with a thermal power of 3 kW has been carried out by studying material compatibility and both steady state and transient thermal loads (Fig. 1). Material selection study for beam dump is carried out by comparing radioactivity generation and thermomechanical properties of different materials. Nickel was found out to generate least activity and copper have good thermal properties. So irradiating cone of copper with a 50-micron nickel coating is finalized. A steady state temperature rise of 28 K and thermal cycling of 2 K is simulated. The peak thermal-structural equivalent stress was analyzed to be 19 MPa, which is within acceptable limits. SS shroud (Fig. 2) of the beam dump is successfully fabricated using conventional fabrication techniques. It is machined as five segments and then welded together. Sheet rolling and electroforming techniques were explored to fabricate irradiating cone. An irradiation cone is developed using sheet rolling process with a 3 mm thick aluminum sheet (Fig 3). Electroforming route is observed to be capable of producing copper conical shells of close tolerance and circularity. Electroforming trials performed to fabricate scaled down (1/4th) prototypes of irradiating cone were successful (Fig. 4). Process parameters for electroforming are finalized. Material properties of electroformed copper are tested and found satisfactory.

|

Fig.1: Temperature rise contour plot

|

Fig.2: Fabricated beam dump with aluminum cone

|

Fig.3: Aluminum Irradiating cone

|

Fig.4: Electroformed cone after removal

|

|

|