| Proton Linac Development Division |

|

|

|

Design of Spallation Target for 1 GeV Proton Beam

Charged particle of 1 GeV will be bombarded on the high atom density material for the production of neutrons which will be guided to neutron tubes for various R & D purposes. Apart from neutrons huge amount of heat is also produced during the spallation process, which needs to be removed. Spallation targets are those elements of a Spallation Neutron Source that generates neutrons upon irradiating with a high energy proton beam. The proton beam interacts with target materials and knocks-off neutrons from it. In this process the proton beam deposits energy associated with it in the target material, which is manifested as heat generation in the same. The proton beam energy is in the order of hundreds of kW to MW such that thermal management is critical. For the kW class beams solid targets are used and for MW class beams, liquid and rotating solid targets are used.

|

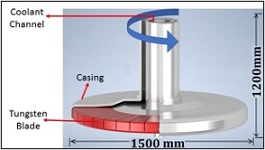

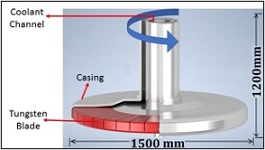

Design of Rotating Spallation Target

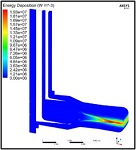

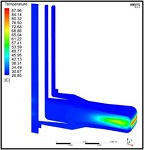

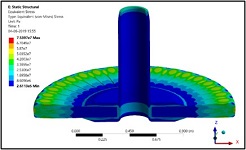

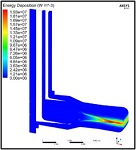

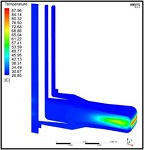

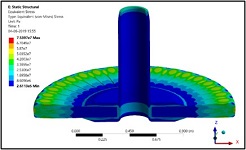

A rotating target is a novel concept to dilute the heat generation and radiation damage on a solid target by rotating it. Fig.1 shows the rotating target model. Tungsten blades are indicated with red color. The casing is of aluminum and other structural members are made up of SS. Helium gas is used as the coolant. Fig.2 is the simulated energy deposition by proton beam on rotating target computed using in-house developed ray-tracing code. Fig.3 is the resulting temperature rise profile and Fig.4 is the resulting thermal and inertial stress profile. The steady state peak temperature (88oC), and equivalent stress on tungsten blades (76 MPa) suggests the feasibility of Rotating spallation target concept.

|

Fig.1: CAD model of rotating target

|

Fig.2: Energy deposition by proton beam on the rotating target

|

Fig.3: Temperature rise in the rotating target

|

Fig.4: Equivalent Stress on rotating target due to thermal and inertial loads

|

|

Design Analysis for Liquid Metal Target

Flowing liquid metals are one of the candidates for the target station due to their high heat removal capabilities. Incident beam falls on very small section of targets station and generates heat locally. This needs to be removed and temperature should be kept with-in limits. Flowing liquid metal (LM) allows to move heated zone away from the beam interaction zone and cool it elsewhere. Mercury is preferred liquid metal because of its higher atom density and it is liquid at room temperature. Flow path has been designed for liquid metal target. Fig.5 shows flow path in target station. To check effectiveness of flow path CFD analysis has been carried out with a constant heat source of 1 MW. Flow path and temperature has been predicted for present design. Fig.6 shows volumetric heat deposition in LM target. Fig.7 and 8 show velocity and temperature distribution in target module, respectively.

|

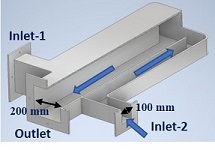

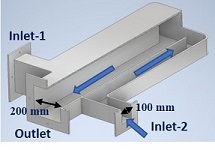

Fig.5: Cad model & fluid path for liquid metal target station

|

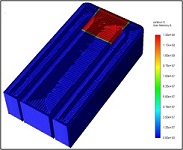

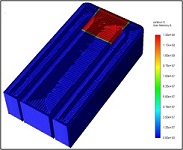

Fig.6: Volumetric heat source (W/m3) in fluid domain

|

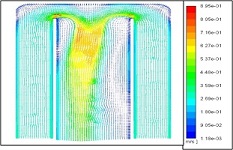

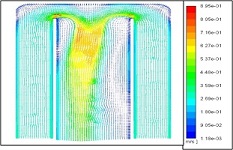

Fig.7: Velocity distribution in liquid metal target

|

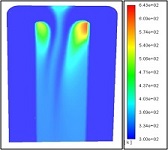

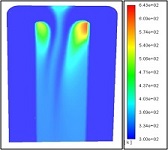

Fig.8: Temperature distribution in LM target

|

|

|

|