|

|

| Laser Materials Processing Division |

|

Laser Surface Treatment for Industrial Applications

|

Laser Shock Peening (LSP) of Spring Steel for Automotive Applications

- The study was taken up to evaluate LSP process for automobile components (particularly leaf springs) as a possible alternative to existing shot peening practice.

- Enhanced fatigue resistance of laser peened components would help in designing the components with reduced cross-section, thereby translating into reduced packaging space & weight reduction for higher fuel efficiency.

Highlights:

- LSP introduced ~ 370 µm thick compressed layer with surface stress of -300 to -450 MPa, without adversely affecting mean surface roughness.

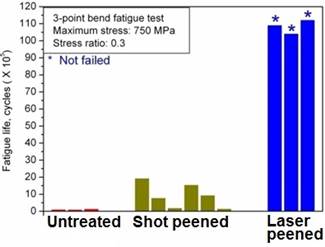

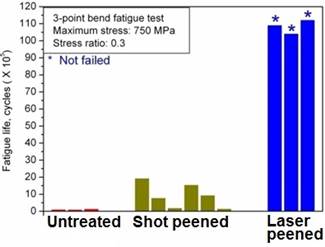

- Laser peened specimens exhibited more than five times increase in fatigue life over conventionally shot peened specimens (Fig.1).

|

|

Fig.1: Comparison of fatigue lives of untreated, shot peened & laser peened SAE 9260 spring steel specimens. |

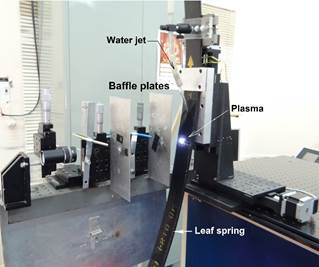

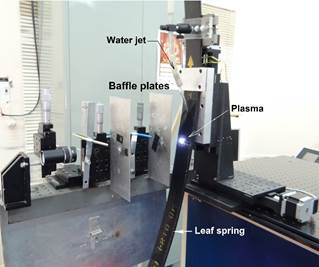

Fig.2: Laser shock peening of automobile leaf spring. |

Publication: P. Ganesh et al., Optics & Lasers in Engineering, 50, 2012, 678-686.

|

|

|