|

|

| Laser Materials Processing Division |

|

Materials joining for in-house applications

|

Brazing of GLIDCOP® to OFE copper for photon absorbers of Indus-2

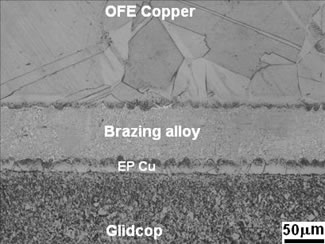

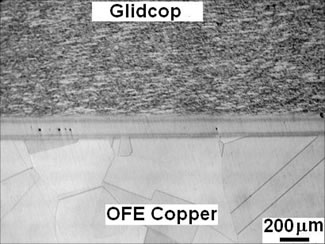

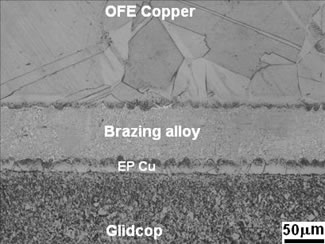

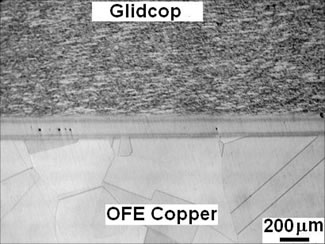

- In the upgraded design of photon absorber of 2.5 GeV synchrotron radiation source Indus-2, the bottom part, facing SR, is made of Glidcop® (oxide dispersion strengthened copper) while its intermediate part is made of OFE copper which needs to be joined to the bottom part.

- Dissimilar joint between GLIDCOP® to OFE copper should be hermetically sealed (He leak rate < 2 x 10-10 mbar.lit/s), bakeable upto 150°C and reasonably strong to withstand high water pressure.

Highlights:

- Two different brazing recipes were evaluated viz. (i) using BVAg-8 braze filler metal while using copper plating on Glidcop part as diffusion barrier and (ii) using 50Au/50Cu as braze filler metal.

- Brazed joints made with both brazing alloys displayed:

- full braze penetration;

- helium leak rate ≤ 2 x 10-10 mbar.lit/s.

- bakeability (sustained 6 thermal cycles (RT - 150°C, soaking for 8 hrs, cooling to

room temperature)

- Shear strength:

= 128 MPa (braze filler: BVAg-8)

= 163 MPa (braze filler: 50Au-50Cu)

|

|

Fig.1: Cross-section of GLIDCOP® to OFE copper brazed joints made with (left) BVAg-8 and (right) 50Au-50Cu braze filler metals. |

Publications: D. P. Yadav et al, Journal of Physics: Conference Series, 390(1), 2012, 012019.

|

| |

|

|