| Laser Power Supplies Division |

|

Control and data acquisition systems for High Power Laser.

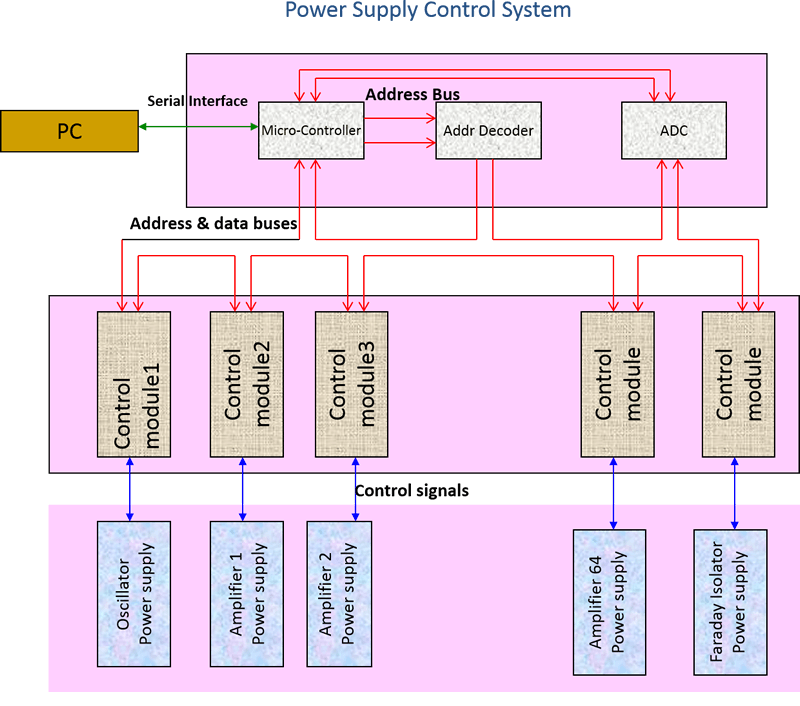

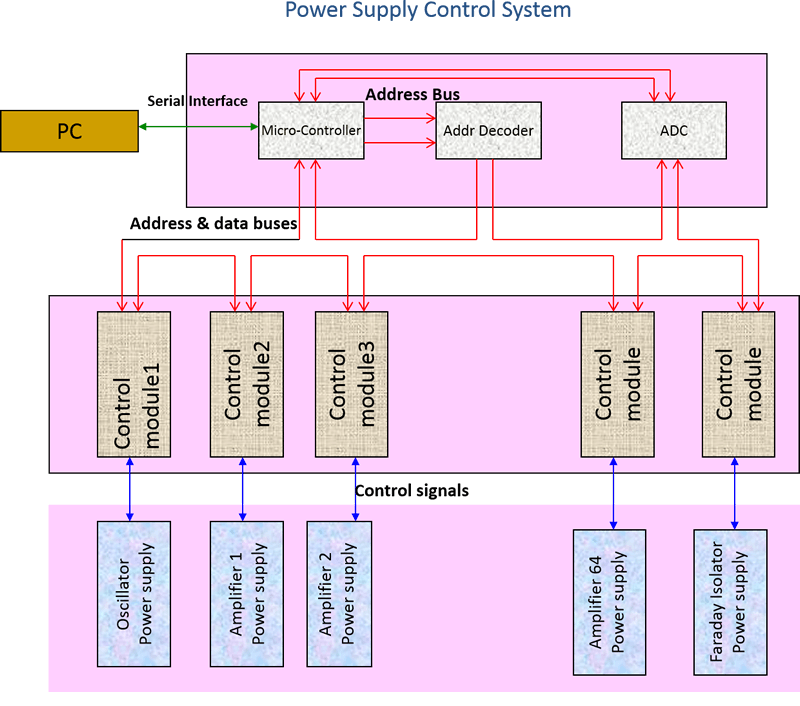

1. Power Supply Control System

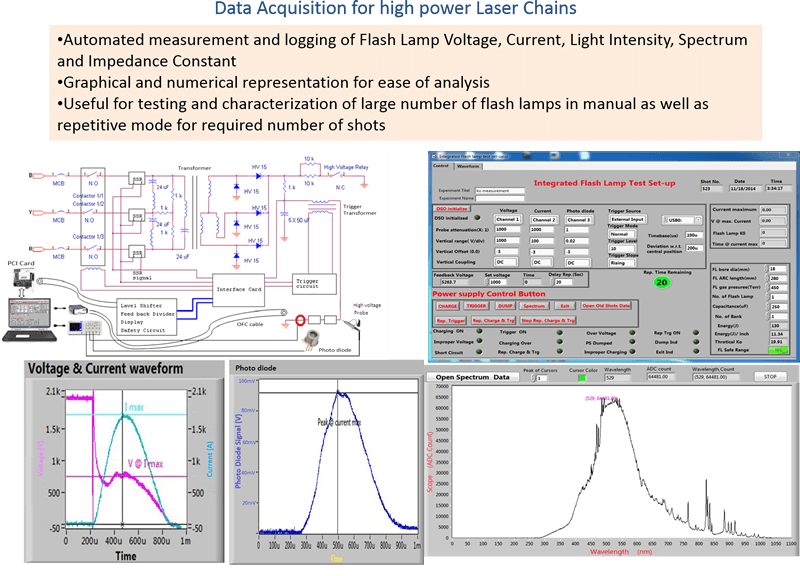

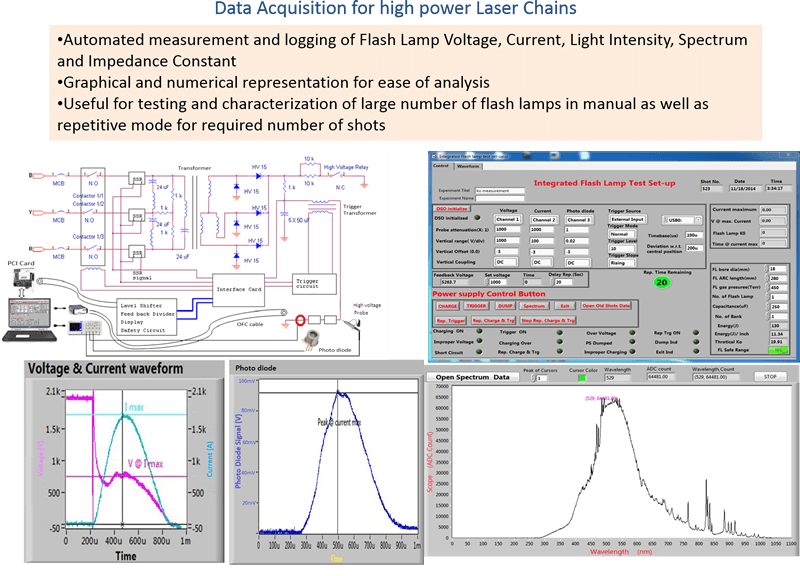

2. Data Acquisition for high power Laser Chains

3. PXIe based control system for MOPA based High Power Laser(HPL)

1. Power Supply Control System:

High power laser control system provides user-friendly data entry, monitoring and interlock circuit. Control systems are designed for synchronised charging and firing of pulse power supply for flash lamp pumped solid-state lasers operating in Master oscillator Power Amplifier (MOPA) configuration. Controller cards and modules are developed in order to interface with power supplies. Control system is designed for switching injector and ejector stages of regenerative amplifier for table top terawatt Nd: Glass laser chain project. Following important safety features are incorporated in the power supplies and control systems are:

1. Short circuit, over charging and self-firing protection.

2. Safe dissipation of remnant energy on capacitor banks.

Power Supply Control System

2. Data Acquisition for high power Laser Chains:

Data Acquisition for high power Laser Chains

Laser Power Supplies Division has developed automated data acquisition and monitoring systems for 2-beam high power Nd: Glass Laser chain. The data acquisition unit acquires information of current pulse, voltage, flash lamp emission power and spectrum. This information is presented in a tabular and graphical mode through GUI, front end.

3. PXIe based control system for MOPA based High Power Laser(HPL)

A PXIe based system has been developed for operation, control and data acquisition in HPL system. PXIe offers highly configurable hardware and software development platform for all control operations, as mentioned above, in MOPA based HPL chains. The control system is currently configured to provide control and synchronised operation of laser oscillator and up to four laser amplifier power supplies through PXIe multifunction analog/digital module and counter/timer module. Application program for user data entry, operation, control, data acquisition and analysis has been been developed using graphical programming approach by standard engineering software. It features password protected user login to prevent unauthorized personnel from operating the HV power supplies which is part of safety procedures stipulated for HPL operation. The application software provides ease of data entry, operation and display of post operation results through user friendly GUI. Figure 1 shows the developed control system and figure 2 shows a typical screen-shot of GUI.

|

|