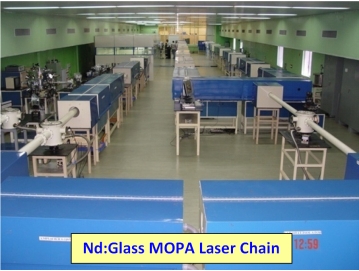

Hundred-Joule, nanosecond-pulse Nd:Glass MOPA laser chain

High energy Nd:Glass (Phosphate) laser chain based on the Master Oscillator Power Amplifier (MOPA) scheme has been indigenously developed and regularly operated at 40 J/ 1ns level for various laser plasma experiments. The laser chain consists of Nd:YLF oscillator, sequence of Nd:Glass rod amplifiers which are pumped by xenon flash lamps, image relay cum vacuum spatial filters, Faraday isolators etc. Laser pulses of energy 10 mJ are generated in the Q switched Nd:YLF oscillator and subsequently amplified in series of Nd:Glass rod amplifiers with successively increasing diameter from 10 mm to 80 mm. The laser beam is magnified and relayed from one amplifier to other amplifier using image relay system. The laser beam is spatially filtered using a low pass vacuum spatial filter. The flash lamps are energized by inhouse developed capacitor bank charging power supplies and control system.

Development of 1 kJ High Energy Nd:Glass laser system

Modern High energy Nd: Glass laser (HEL) systems are based on space multiplexed MOPA (Master Oscillator Power Amplification) architecture, delivering multiple laser beams of desired characteristics and kilojoules of energy for laser-matter interaction applications. The seed laser pulse of desired temporal, spatial and spectral characteristics is generated by a master oscillator, which is subsequently amplified to higher energies in high gain pre-amplifiers and multi disc- multi pass power amplifiers. These HEL lasers basically consists of fiber front end, high gain pre-amplifiers, long arm multi pass beam injection cum spatial filters, flash lamp pumped Nd:Glass power amplifiers, plasma electrode Pockels cell, deformable mirrors etc.

Following developments as elaborated below have been carried out pertaining to achieving this:

- Fiber Optic Front End System (FOFES)

- Multi stage joule level pre-amplifier systems.

- Physics prototype of Nd: Glass laser system.

- 12-disc, Nd: Glass Amplifier module.

- Edge cladding of large sized Nd: phosphate Glass disc

1. Fiber Optic Front End System (FOFES)

High Energy Lasers (HEL) require a front end to provide seed signal pulses with desirable spectral, temporal and spatial characteristics. All fiber optic front end seed laser system is ideally suitable for high energy Nd:glass lasers as it generates seed pulses with desired temporal pulse width and pulse shape. Commercially available pulsed lasers such as Q-switched or mode locked lasers are not suitable for this application as user cannot control pulse shape and pulse width with required accuracy. Hence, FOFES is developed based on external modulation scheme starting with a CW laser source for the aforementioned application. All fiber architecture has been used due to inherent advantages such as alignment-free operation, ruggedness, compact and non-existent atmospheric exposed intermediate optical surfaces except for single surface exposure at output port. Initially an engineered one-arm FOFES that generates linearly polarized collimated beam in TEM00 mode with pulse energy of 20 nJ/ beam, pulse width of 3 ns and repetition rate of 100 kHz at 1053 nm has been developed. Subsequently, an engineered two beam FOFES that generates time synchronized linearly polarized collimated beams in TEM00 mode with pulse energy of 40 nJ/ beam, pulse width of 3 ns and repetition rate of 100 kHz at 1053 nm has been developed to seed a two beam Nd: Glass 1 kJ laser system being developed at RRCAT.

Towards meeting the needs of future multi-beam multi kJ HELs, an engineered 8-beam FOFES that generates eight linearly polarized beams in TEM00 mode with pulse energy of 10 nJ/ beam, pulse width of 3 ns and repetition rate of 100 kHz at 1053 nm has been developed. A narrow line width CW fiber laser is the first stage of the system. The laser is followed by a two-stage external modulation process to generate pulses with required width, shape and repetition rate. The first stage of modulation is based on a RF driven Acoustic Optical Modulator that reduces average power without affecting peak power, for generating laser pulses with a pulse width of 300 ns. The second stage of modulation is a pulse generator driven Intensity modulator. The intensity modulator is operated at a point of minimum transmission through a single operating (minimum transmission) point modulation control board. The operating point of intensity modulator is then modulated by an arbitrary waveform generator of 2.85GS/s through an RF amplifier. The system generates arbitrary shaped laser pulses with pulse energy of about 150 pJ and a pulse width of ~3 ns at λ = 1053 nm. A trigger generator is used to synchronize both modulator sub-systems against internal residual delays. A fiber optic Yb doped amplifier has been introduced after dual modulation stages for amplification of pulse energy to about 150 nJ. At this point, 8-beam fiber optic split-cum-delay module has been introduced into the system. A pulse energy of more than 10 nJ /arm was obtained after splitter system.

8 beam all-fiber front end system

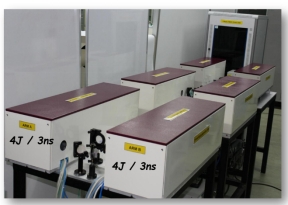

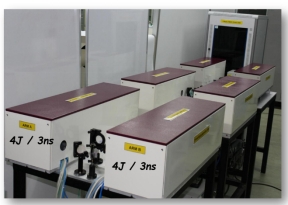

Two-beam pre- amplifier system

2. Multi stage joule level pre-amplifier systems

The HEL laser systems use fiber based front end system as seed pulse generator. However, due to low energy handling capabilities of fiber front end, the output energy from them is limited to nJ level. Whereas Nd: Glass power amplifiers require input laser pulses of mJ to joule level energy, for amplifying further to hundreds of joules. Thus, intermediate pre-amplifiers with high gain are required to meet the input energy requirements of the power amplifiers.

Initially, a three-stage joule level prototype pre-amplifier system capable of amplifying 40 nJ/3ns laser pulses to energy more than 6J/3ns reliably with overall gain of > 108 has been developed. The system consists of a diode pumped four pass Nd:YLF and two stages of double pass Nd:Glass rod based amplifiers. The seed laser pulses of energy 40 nJ are amplified to 8 mJ by the Nd:YLF amplifier in four pass configuration with gain of 2 X 105. These laser pulses are further amplified to ~ 300 mJ in first stage and to 6J in second stage of Nd: glass amplifiers.

In order to seed the power amplifiers of two beam HEL laser system being developed at RRCAT, a two-beam engineered two beam laser pre-amplifier system capable of providing laser pulses of energy more than 4 J/3ns per arm with overall gain of 108 has been developed. The input laser pulses are generated in engineered two-beam FOFES capable of providing temporally shaped and time synchronized 40 nJ seed laser pulses of 3 ns duration. The laser pulses are further amplified in diode pumped four pass Nd:YLF and two stages of double pass Nd:Glass amplifiers. The output energy of the pre- amplifier system can be varied from about 10 mJ to about 4J. All the subsystems have been engineered to modular assembly for ease of integration and deployment.

3. Physics prototype of Nd: Glass laser system

For validation of the subsystems of HEL, carrying out characterization of laser discs, optimizing pump parameters, gain measurements and validation of four pass amplification geometry, a prototype Nd:glass laser system has been designed and developed. The system consists of a Q-switched Nd: YLF oscillator, pre- amplifier system, long arm vacuum spatial filter for laser beam injection, ejection & 4-pass amplification and flash lamp pumped Nd:Glass discs amplifier. The seed laser pulses are generated in a Q-switched Nd: YLF oscillator with energy of 5 mJ /10 ns. These pulses are amplified to 12 J in the pre-amplifier system which are then seeded to the disk amplifier.

Initially, a flash lamp pumped 4-disc Nd:Glass amplifier has been developed to study design feasibility and characterize gain in discs, flashlamp pumping configuration, power supplies, control unit etc. The amplifier module consists of four Nd:Glass disc placed at Brewsters angle in 2 x 2 array in sealed housing. The amplifier housing is a SS chamber having optical windows for laser entrance and exist and a set of blast glasses for shielding the laser discs in case of catastrophic explosion of flash lamps mounted on the housing. The discs are optically pumped by a set of 24 Xenon flash lamps each having 40 cm arc length placed close to the glass discs and blast glass. In this amplifier, laser pulses of energy 12 J were amplified to 21 J in four pass configurations.

12-disc Nd: glass amplifier

4. 12-disc, Nd: Glass Amplifier module

As a precursor to 500 J laser system, a 12-Disc Nd:Glass amplifier that can accommodate twelve glass discs with required subsystems has been designed, fabricated, assembled and characterized. Various subsystems of the amplifier are disk amplifier housing, long arm, vacuum spatial filter cum beam injection system, 10 kV capacitor charging power supplies and control system. The amplifier housing is a 2-meter-long SS-Aluminum chamber in which twelve Nd: glass discs are mounted in linear geometry. These Nd: glass discs are pumped by 72 numbers of xenon filled cerium doped quartz flash lamps A long arm vacuum spatial filter (VSF) cum beam injection system was also integrated to the disk amplifier assembly which has two plano-convex lenses each of focal length 7.5 m, HR mirrors for beam injection and ejection. The flash lamps are energized by six 10 kV capacitor charging power supplies, pre-ionization units and control system.

The seed pulses from pre-amplifier system are fed to the 12-disk amplifier through long arm VSF with a beam injection lens of focal length 2.5m and a 45-degree HR Mirror. The laser beam makes 4-passes in the amplifier and ejected after forth pass through long arm VSF. At electrical pump energy of ~ 360 kJ, seed laser pulses of energy ~ 6 J are amplified to more than 150 J.

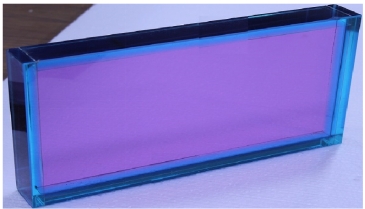

5. Edge cladding of large sized Nd: phosphate Glass disc

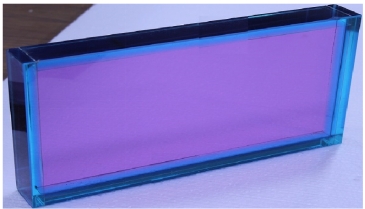

Edge cladding of Nd: glass discs is required in high energy lasers to prevent the parasitic lasing within the laser discs which would otherwise deplete the amplifier gain. In this direction, the process involved in edge cladding of Nd: Glass disc has been established and an edge cladded Nd: Glass disc of size 320 mm x 170 mm x 40 mm was developed. The development process includes studies on identification of suitable epoxy-based adhesives, qualifying adhesive for the desired parameters, polishing of Nd: Glass and clad glass discs, bonding of clad glass on large sized Nd: glass disc, studies on stability of the bonded joint under effect flash lamp irradiation etc.

Initially, Nd: Glass slab & clad glass slabs were sized and the edges were optically polished to ~ λ/4 level. The clad glass slabs were bonded to all the four edges of Nd: glass discs using the qualified adhesive, cured under UV radiation, irradiated for 1000 shots of flash lamps radiation at 15 J/cm2 and tested for reflectivity and chemical stability.

Edge cladded Nd: Glass disc of size 320x70x40 mm3

|